Desulphurization of Hot Metal – IspatGuru

Dip lance process is the most economical, effective and reliable method of desulphurization hot metal It consists of pneumatic injection of fine grained desulphurization reagent into the hot metal with high dosing precision via a dispensing vessel and a refractory lined lance For each reagent, one separate dispensing vessel is usedHot metal desulphurisation process > Metallurgical injection also reliably carries out targeted modification of the desulphurisation reagent injection rates and the conveying gas flow rates during active hot metal Hot Metal De Sulphurisation Hot Metal De Sulphurisation : JSW Steel Ltd Process Engineer IIM, sri satya sai hot metal desulphurisation processthe process model led to an improved efficiency of the desulphurisation treatment To better understand the pickup of reaction products into the slag layer, samples from the hot metal top layer just below the slag, taken after the injection of reagents, have been analysed 2 Process Advanced Process Modelling of Hot Metal it usually takes 8 hours to get hot metal at the furnace bottom The reduction reactions can be described to take place as follows: Fe 2 O 3 → Fe 3 O 4 → FeO → Fe The hot metal from the blast furnace contains high contents of carbon, usually about 45% This high content of carbon is beneficial for the desulphurization of hot metalA prestudy of Hot Metal Desulphurization Desulphurization of hot metal is the most economic process for removing sulphur before charging to the BOF Metallic Magnesium is the most effective reagent for desulphurization; calcium oxide is the most costeffective solution and the formed Hot Metal Desulphurization Carmeuse

Operational Costs of Hot Metal Desulphurization

In the desulphurization of hot metal powdered reagents are injected into the hot metal The reagents chemically react with the dissolved sulfur forming sulphides that ascend and are captured in the upper slag layer that covers the hot metalHot metal desulfurization is commonly conducted in a ladle or a torpedo car, 1 using a desulfurization reagent that is either injected into the metal bath or added on top of it 2 From the thermodynamic point of view, the fundamental requirement for the desulfurization reagent is to be able to donate electrons and form a new sulfide‐binding phase 3 Typical reagents used in the industry are calcium carbide (CaC A Review of Modeling Hot Metal Desulfurization Hot metal desulphurisation serves as the main unit process for removing sulphur in blast‐furnace based steelmaking This study reviews the available body of literature on modelling hot metal desulphurisation A Review of Modelling Hot Metal Desulphurisation In a steel plant in China, hot metal is desulphurised in the 210 t transfer ladle by injection of 60% Mg and 40% CaO using nitrogen as a carrier gas With the adjustment of product structure, the proportion of the deep desulfurization hot metal increased to more than 95% Some problems, the high consumption of desulfurizer, the large amount ofOptimization of Desulphurization Process using Lance In order to ensure the efficiency and flexibility of hot metal desulphurisation, desulphurisation agents are injected in mono or coinjection processes For the coinjection process, a plant must have different hardware configurationsHot metal treatment SMS group

hot metal desulphurisation process

Hot metal desulphurisation process > Metallurgical injection also reliably carries out targeted modification of the desulphurisation reagent injection rates and the conveying gas flow rates during active hot metal Hot Metal De Sulphurisation Hot Metal De Sulphurisation : JSW Steel Ltd Process Engineer IIM, sri satya sai Desulphurization of hot metal is the most economic process for removing sulphur before charging to the BOF Metallic Magnesium is the most effective reagent for desulphurization; calcium oxide is the most costeffective solution and the formed sulfides are very stableHot Metal Desulphurization Carmeusethe process model led to an improved efficiency of the desulphurisation treatment To better understand the pickup of reaction products into the slag layer, samples from the hot metal top layer just below the slag, taken after the injection of reagents, have been analysed 2 Process Advanced Process Modelling of Hot Metal HIsarna is a smelting reduction ironmaking process that is currently in the pilot plant development phase HIsarna produces hot metal with higher sulphur, lower phosphorus and manganese, almost no silicon and titanium and a lower temperature compared to the blast furnace Because of that, desulphurisation of the HIsarna hot metal is one of the challenges to ensure its use for steelmakingDesulphurisation of Hisarna hot metal: a comparisson study Optimisation of hot metal desulphurisation slag in the CaO/Mg coinjection process to improve slag skimming performance Zushu Li 1,*, Mick Bugdol 1 and Wim Crama 2 1) Tata Steel RDT, Swinden Technology Centre, Rotherham, United Kingdom 2) Tata Steel RDT, IJmuiden Technology Centre, IJmuiden, the Netherlands Optimisation of hot metal desulphurisation slag in the

Optimization of Desulphurization Process using Lance

of the hot metal and the total injection time were the initial conditions of the model The mathematical model was calculated by using the MATLAB program, with an algorithm based on an explicit Runge–Kutta (4) formula The instantaneous concentration of sulfur in the hot metal in the desulfurization process was obtainedThis process of removing impurities from molten metal in advance before charging it into a converter furnace is called hot metal preliminary processing The KR Hot Metal Desulfurization System developed by Steel Plantech will achieve highlevel desulfurization efficiency as well as contribute to KR Hot Metal Desulfurization System Steel Plantech Zushu Li, Mick Bugdol and Wim Crama, Optimisation of hot metal desulphurisation slag in the CaO/Mg coinjection process to improve slag skimming performance Technical Report, Tata Steel RDT, Swinden Technology Centre, Rotherham, United Kingdom Google ScholarRefractory for Hot Metal Transport and Desulfurization Desulphurisation of HIsarna hot metal HIsarna is a new ironmaking process that is being developed at Tata Steel IJmuiden that reduces CO 2 emissions HIsarna hot metal (HsHM) has a different composition compared to normal hot metal (HM) from a blast furnace (BF); notably much higher sulphur [1,2] Fig 1 HM composition and temperature vs Mg Sulphur removal in iron and steelmaking ABSTRACT To lower the iron losses of the hot metal desulphurisation (HMD) process, slag modifiers can be added to the slag Slag modifiers decrease the apparent viscosity of the HMD slag Most common slag modifiers in industry contain fluoride as Lowering iron losses during slag removal in hot metal

hot metal desulphurisation process

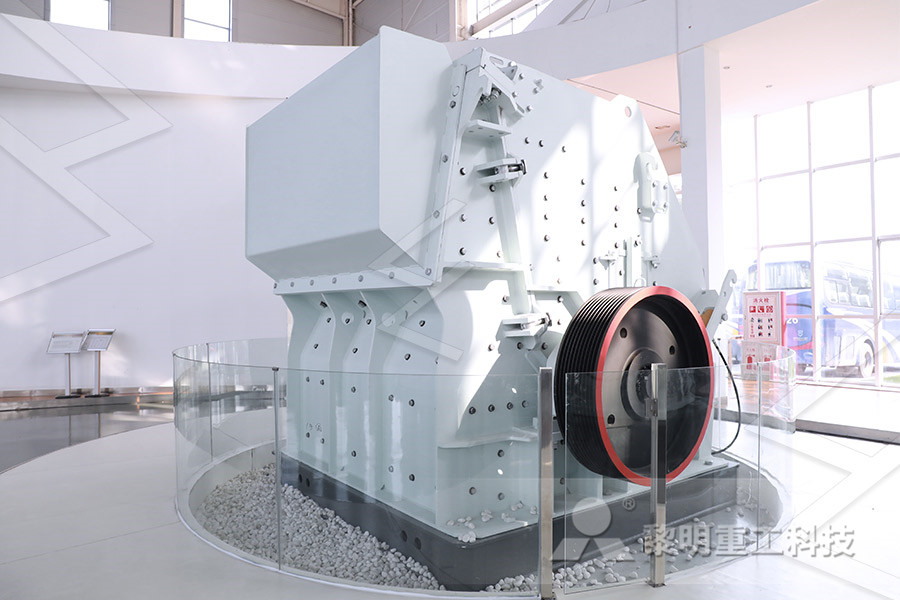

Hot metal desulphurisation process > Metallurgical injection also reliably carries out targeted modification of the desulphurisation reagent injection rates and the conveying gas flow rates during active hot metal Hot Metal De Sulphurisation Hot Metal De Sulphurisation : JSW Steel Ltd Process Engineer IIM, sri satya sai hot metal desulphurisation process GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementshot metal desulphurisation process3 A process for desulfuring molten metal comprising: injecting a desulfurization reagent into the molten hot metal by a carrier gas via a lance immersed in said molten hot metal; said desulfurization reagent comprising magnesium nitride 4 The process of claim 3 wherein said molten hot metal is molten steel 5Process for desulfurization of molten hot metals The In the theoretical part of the thesis, the most common methods for desulphurisation of hot metal are presented, as well as the main reactions and reaction mechanisms of the CaObased reagent injection The desulphurisation of hot metal occurs mainly as a reagentmetal reaction, but in this thesis the emphasis is on the slagmetal reactionInitial Slag in Primary Desulphurisation of Hot MetalHIsarna is a smelting reduction ironmaking process that is currently in the pilot plant development phase HIsarna produces hot metal with higher sulphur, lower phosphorus and manganese, almost no silicon and titanium and a lower temperature compared to the blast furnace Because of that, desulphurisation of the HIsarna hot metal is one of the challenges to ensure its use for steelmakingDesulphurisation of Hisarna hot metal: a comparisson

EOSC 021 Schrama Effect of KAlF4 on the efficiency of

(UK) the hot metal from the blast furnace (BF) is desulphurised before it is charged to the steelmaking converter Two hot metal desulphurisation (HMD) stations are available to desulphurise the hot metal by coinjection of magnesium and lime This HMD process is required to Zushu Li, Mick Bugdol and Wim Crama, Optimisation of hot metal desulphurisation slag in the CaO/Mg coinjection process to improve slag skimming performance Technical Report, Tata Steel RDT, Swinden Technology Centre, Rotherham, United Kingdom Google ScholarRefractory for Hot Metal Transport and desulphurisation capacity of HIsarna An industrial HIsarna will be able to produce HM with less S than is depicted in Table 1 [1], [3] 2 Theoretical analysis 21 Desulphurisation with Mg and CaO The mechanism of hot metal desulphurisation (HMD) via coinjection of Delft University of Technology Desulphurisation of Process for processing pig iron desulphurization slag, the pig iron desulfurization slag being mechanically processed in a preparation step (1), the pig iron desulfurization slag being washed in a container with an aqueous medium in a processing step (2) following the preparation step, with a separation step (3) during the Processing step (2) the hot metal desulphurisation slag is exposed to DE9B4 Treatment process for hot metal Desulphurisation of HIsarna hot metal HIsarna is a new ironmaking process that is being developed at Tata Steel IJmuiden that reduces CO 2 emissions HIsarna hot metal (HsHM) has a different composition compared to normal hot metal (HM) from a blast furnace (BF); notably much higher sulphur [1,2] Fig 1 HM composition and temperature vs Mg Sulphur removal in iron and steelmaking